COMPANY OVERVIEW

MISSION

Drive semiconductor breakthroughs that define the next generation.

Guiding Principles

- Think customer, company, and individua

- Be number one in customer trust

- Attract, retain, and develop the best talent

- Deliver best-in-class solutions

- Achieve financial goals to deliver shareholder value

- Act with purpose for a better world

CORE VALUES

- Achievement

- Agility

- Honesty & integrity

- Inclusion & diversity

- Innovation & continuous improvement

- Mutual trust & respect

- Open communication

- Ownership & accountability

- Teamwork

Want to reach out to Silfex?

KEY MILESTONES

Technology has come a long way since our early days, and we are proud of our role in connecting the world via the semiconductor industry

2024

Eaton facility expands, bringing the company to 625,000 square feet across both sites2020

Springfield crystal growing operation expands2019

Springfield facility opens, bringing the company to more than 500,000 square feet across both sites2018

Silfex announces expansion into Springfield, Ohio2016

The Silfex business doubles in size at the original facility in Eaton, Ohio2009

Silfex is established2006

Lam Research acquires Bullen's silicon growing and processing assets1971

Bullen Ultrasonics founded

CUSTOMER SERVICE

Whether scheduling, checking an order status, resolving customer issues, or troubleshooting, the Silfex team of experts is available to quickly answer customer questions and resolve specific requests. As the single point of contact for all customer issues, Customer Service coordinates our interdisciplinary teams of engineers and quality resources to resolve all issues completely and rapidly. Our focus is responsiveness and accuracy and providing best-in-class silicon components for our customers.

ENGINEERING EXPERTISE

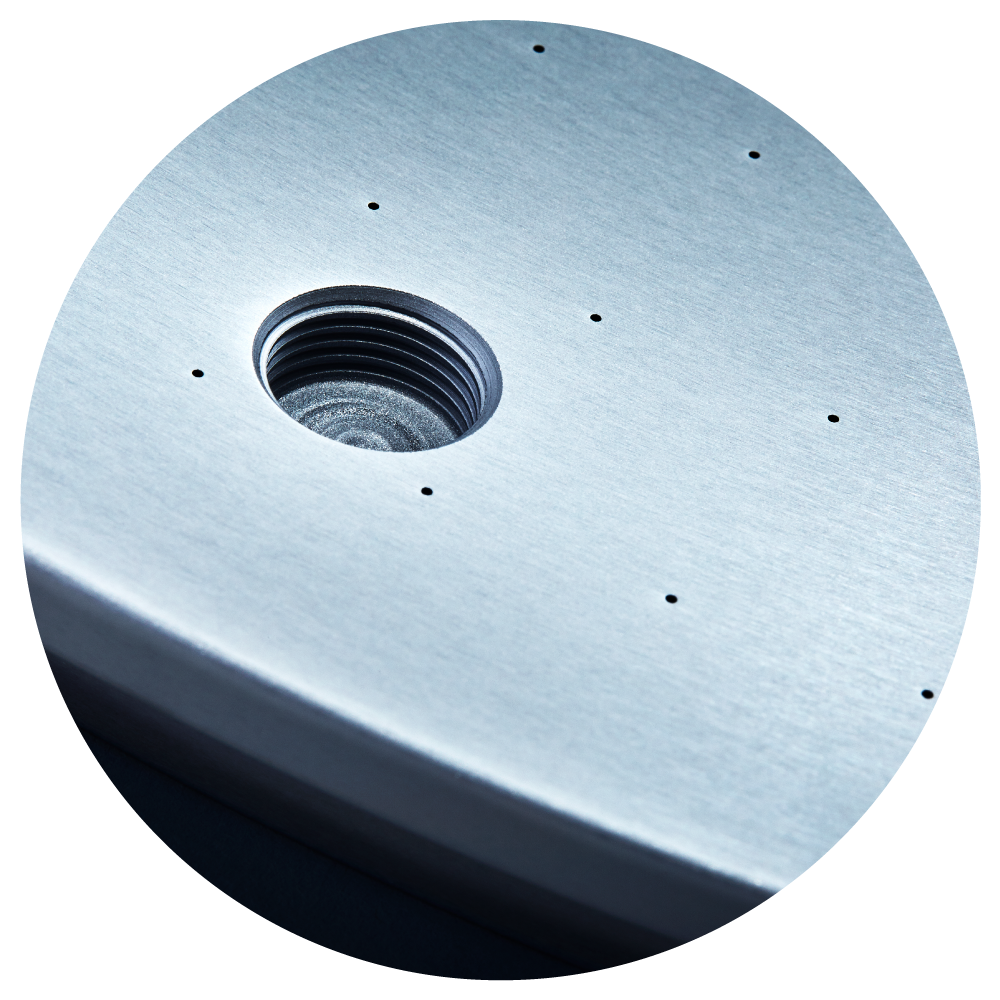

Our engineers have extensive experience in processes, manufacturing, and design, combined with specialized knowledge in materials, mechanical, chemical, and electrical disciplines that deliver the best possible components. We’re also skilled at working with technically challenging materials such as silicon and silicon carbide.

Customers can request an engineering consultation of proposed designs that may include Design for Manufacturing improvements, review of material and machining choices, optimization for gas distribution, or other recommended actions that improve performance and reduce costs. Our production experts can assist with complex integration challenges including bonding, precision cleaning, and packaging for distribution.

Learn more about how we make our silicon components on our Processes page.